BEAR Brand Ceramic Tile Powder Spray Dryer Factory

Product details of the Ceramic tile powder spray dryer

Product Overview

Designed with a built-in automatic fan, BEAR Ceramic tile powder spray dryer is created with the purpose of circulating the warm wind evenly and thoroughly inside. The product is not affected by the weather condition. Unlike the traditional drying method including sun-dry and fire-dry which highly rely on good weather, this product can dehydrate food whenever and wherever. Ceramic tile powder spray dryer is widely used in various scenes. This product only consumes little power. Users will find out how energy efficient it is after they receive the electricity bills.

Product Information

Next, will show you the details of Ceramic tile powder spray dryer.

Main application

* Chemical Industry: sodium fluoride (potassium), alkaline dyestuff and pigment, dyestuff intermediate, compound fertilizer, formaldehyde silicic acid, catalyst, sulphuric acid agent, amino acid, white carbon black, etc.

* Plastic Resin: AB, ABS latex, urea resin, phenolic resin, dense glue (urea) formaldehyde resins, polyethylene, polyvinyl chloride, etc.

* Food Industry: fat-rich milk powder, lancet protein, cocoa milk powder, babymeal, hunting blood meal, egg white (yellow), etc.

* Food and Plants: oats, chicken juice, coffee, instant tea, seasoning meat, protein, soybean, peanut protein, hydrolyzate and so on.

* Sugar: corn syrup, corn starch, glucose, pectin, malt sugar, potassium sorbate, etc.

* Ceramics: aluminium oxide, ceramic tile material, magnesium oxide, talcum powder, etc.

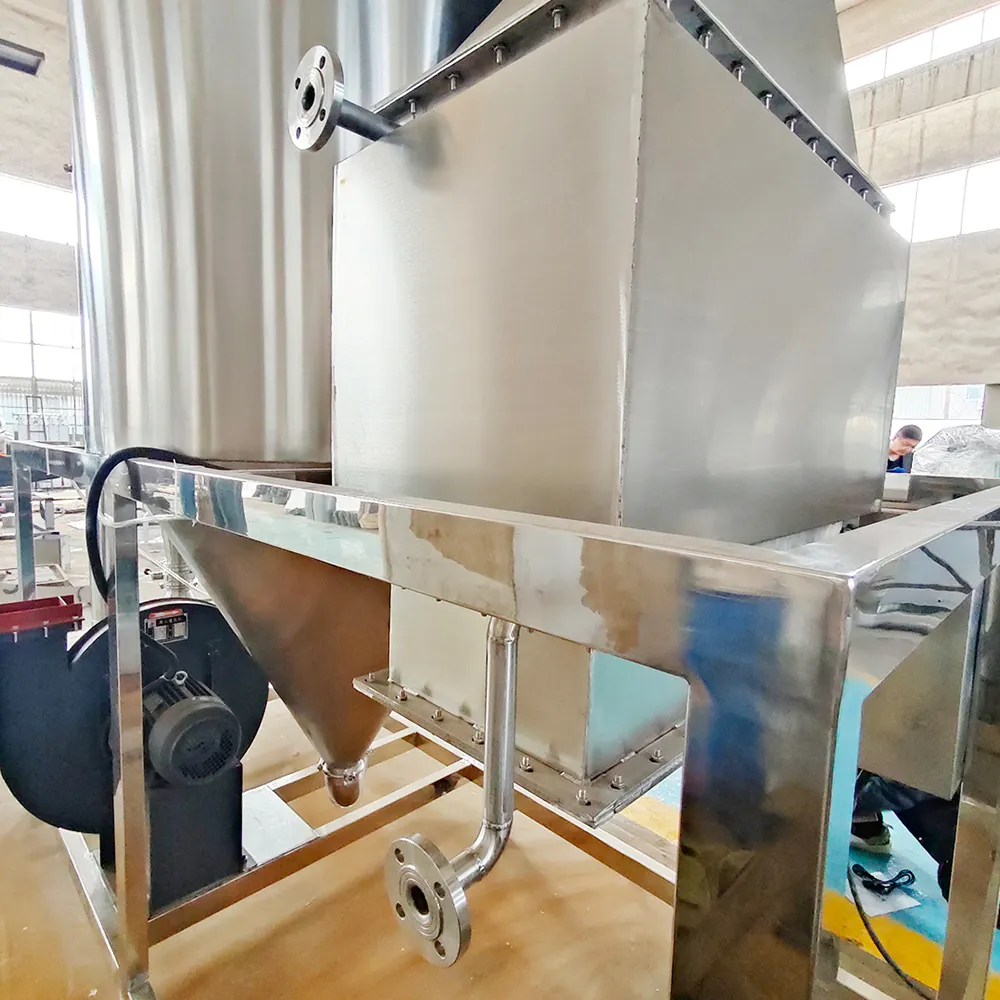

Product display

Related parameters

|

Model |

LPG-5 |

LPG-25 |

LPG-50 |

LPG-100 |

LPG-150 |

LPG-200-2000 |

|

Inlet temperature (℃ ) |

140-350(automatically controlled) |

|||||

|

Outlet temperature (℃ ) |

~80-90 |

|||||

|

Max water evaporation capacity (kg/h) |

5 |

25 |

50 |

100 |

150 |

200-2000 |

|

Centrifugal spraying nozzle transmission method |

compressed air transmission |

mechanical transmission |

||||

|

Rotation speed (r.p.m) |

35000 |

20500 |

17600 |

17600 |

15500 |

11570 |

|

Spraying disc diameter (mm) |

50 |

108 |

120 |

130 |

150 |

180-340 |

|

Heat supply |

Electricity |

electricity, steam |

electricity, steam, fuel oil and gas |

Settled by users themselves |

||

|

Max electric heating power(kW) |

9 |

36 |

63 |

81 |

99 |

/ |

|

Dimensions(m) |

1.8*0.93*2.2 |

3*2.7*4.26 |

3.7*3.2*5.1 |

4.6*4.2*6 |

5.5*4.5*7 |

depends on the concrete conditions |

|

Dried powder collecting |

≥95% |

|||||

Mian Features

1.Fast drying speed; LPG high speed centrifugal spray dryer greatly increasing the surface area of the material after the liquid is atomized; it can instantly evaporate 95% -98% of water in the stream of hot air; it takes only a few seconds to complete drying, which is especially suitable for drying heat sensitive materials.2. Our products have a good uniformity, mobility and solubility, high purity and good quality.3. Simplified production process, easy to operate and control. Liquid of 40-60% moisture content (up to 90% for special materials) can be dried into powder products at a time, without crushing and screening after drying, which reduces production process and improve product purity. The size, bulk density, moisture can be adjusted within a certain range by changing operation conditions. It is convenient to do control and management.

Hot Tags: LPG high speed centrifugal spray dryer, Coffee powder spray dryer, LPG Spray dryer, Catalyst spray dryer, Sodium fluoride spray dryer, Protein powder spray dryer, Formaldehyde silicic acid spray dryer,China, Manufacturers, Suppliers, Factory, Customized

Company Advantages

Situated in hang zhou, Hangzhou Bear Machinery Co.,Ltd. is a high-tech enterprise integrating production, processing, and sales. We are mainly engaged in the business of 清洗烘干生产线,果蔬加工线,中草药处理线. always stands on customer's side. We do everything we can to meet customers' needs. We are committed to providing quality products and caring services. With rich experience and exquisite technology, we are looking forward to building good cooperation with partners from all walks of life and creating a better tomorrow!